Stainless simbi gasket kupedzisa mhando fekitari yakananga kutengesa

Zvinhu Zvenyama

1. Kune chloride ions munzvimbo yekushanda.

Chloride ions inowanikwa mumunyu, ziya, mvura yegungwa, mhepo, ivhu, nezvimwewo. Simbi isina tsvina inoora nekukurumidza kana paine maion echloride kupfuura simbi yakapfava.

Saka kushandisa Stainless simbi zvakatipoteredza ane zvinodiwa, uye kudiwa kazhinji kupukuta, kubvisa guruva, kuramba yakachena uye yakaoma.(Izvi zvinomupa "kushandiswa zvisina kufanira.")

Kune muenzaniso muUnited States: bhizinesi rakashandisa gaba remuoki kubata mushonga une chloride ions.Chigaba chacho chave chichishandiswa kwemakore anopfuura zana uye chakarongwa kuti chitsiviwa muma1990.Nemhaka yokuti zvinhu zvemuouki zvakanga zvisiri zvemazuva ano zvakakwana, mudziyo wacho wakanga wakaora uye wakadeuka mazuva gumi nematanhatu pashure pokunge watsiviwa nesimbi isina tsvina.

2. Hapana mhinduro yekurapa.

Alloy zvinhu hazvina kunyungudika mune matrix, zvichikonzera yakaderera alloy yemukati mune matrix chimiro uye kushomeka kwekushomeka.

3. Zvinhu zvakadaro zvisina titanium uye niobium zvine maitiro echisikigo kune intergranular corrosion.

Kuwedzerwa kwetitanium uye niobium, yakasanganiswa nekurapa kwakagadzikana, inogona kuderedza intergranular corrosion.

Mumhepo kana chemikemikari corrosion medium inogona kuramba kukora kwesimbi yakakwira alloy, simbi isina tsvina inzvimbo yakanaka uye yakanaka corrosion resistance, haifanirwe kunge yakapfachuka uye kumwe kurapwa kwepamusoro, uye kutamba zvinhu zvemukati zvesimbi isina tsvina, inoshandiswa mukati. zvakawanda zvemhando yesimbi, inowanzonzi simbi isina tsvina.Pachinzvimbo chekushanda kwe13 chromium simbi, 18-8 chromium nickel simbi uye imwe yakakwirira alloy simbi.

Kubva pakuona kwe metallographic, nokuti simbi isina tsvina ine chromium uye pamusoro pekugadzirwa kwefirimu yakaonda kwazvo yekromium, iyo firimu yakaparadzaniswa neokisijeni mukupinda kwesimbi yekudzivirira kwemarara.

Kuti uchengetedze kusimba kwekuora kunowanikwa musimbi isina tsvina, simbi inofanira kunge iine zvinopfuura 12% chromium.

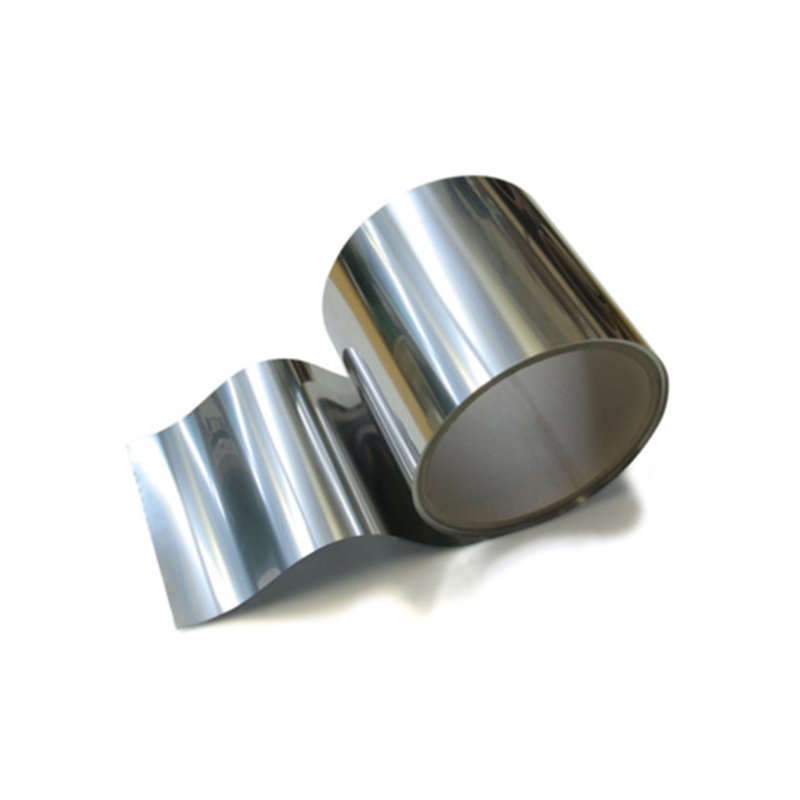

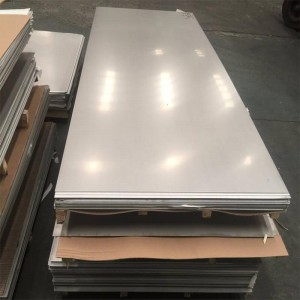

304stainless simbi Shim Plates isimbi yepasirese isina tsvina, iyo inoshandiswa zvakanyanya mukugadzira michina uye zvikamu zvinoda zvakanaka zvakakwana zvinhu (corrosion resistance uye formability).

304 Stainless simbi imhando yesimbi isina tsvina inogadzirwa zvinoenderana neASTM zviyero muUnited States.304 yakaenzana neChina 0Cr19Ni9 (0Cr18Ni9) simbi isina tsvina.304 ine 19% chromium uye 9% nickel.

304 ndiyo inonyanya kushandiswa stainless/heat resistance simbi.Inoshandiswa mumidziyo yekugadzira chikafu / xiton makemikari emidziyo / simba renyukireya, nezvimwe.

304 inoenderana neChinese brand 0Cr18Ni9,1Cr18Ni9Ti, kabhoni yemukati ≤0:08%

304Lstainless simbi Shim Plates mutsauko we304stainless simbi Shim Plates simbi isina simbi ine yakaderera kabhoni yemukati uye inoshandiswa kune welding application.Iyo yakaderera kabhoni yemukati inoderedza kunaya kwecarbides munzvimbo inobatwa nekupisa pedyo neweld, izvo zvinogona kutungamirira kune intergranular corrosion (welding erosion) musimbi isina tsvina mune dzimwe nharaunda.

Parameters

| T | kuoma | kuoma | Kunaya kunoomesa mamiriro ekurapa kupisa | conductive% | ||||||

| kuoma | kuoma | Kusimba kwegohoN/mm | Kusimba kwekusimbaN/mm | elongation% | Kurapa kwekupisa | kuomararaHV | Kusimba kwegohoN/mm | Kusimba kwekusimbaN/mm | ||

| 301-CSP | 1/2H | 340±30 | ≥510 | ≥930 | ≥10 | - | - | - | - | 2.3 |

| 3/4H | 400±30 | ≥745 | ≥1130 | ≥5 | - | - | - | - | 2.3 | |

| H | 460±30 | ≥1030 | ≥1320 | - | - | - | - | - | 2.3 | |

| EH | 510±20 | ≥1275 | ≥1570 | - | - | - | - | - | 2.3 | |

| SEH | ≥530 | ≥1450 | ≥1740 | - | - | - | - | - | 2.3 | |

| 304-CSP | 1/2H | 280±30 | ≥470 | ≥780 | ≥6 | - | - | - | - | 2.3 |

| 3/4H | 340±30 | ≥665 | ≥930 | ≥3 | - | - | - | - | 2.3 | |

| H | ≥370 | ≥880 | ≥1130 | - | - | - | - | - | 2.3 | |

| 631-CSP | 0 | ≤200 | - | ≤1030 | ≥20 | TH1050RH950 | ≥345≥392 | ≥960≥1030 | ≥1140≥1230 | 2.3 |

| 1/2H | 375±25 | - | ≥1080 | ≥5 | CH | ≥380 | ≥880 | ≥1230 | 2.3 | |

| 3/4H | 425±25 | - | ≥1180 | CH | ≥450 | ≥1080 | ≥1420 | 2.3 | ||

| H | ≥450 | - | ≥1420 | CH | ≥530 | ≥1320 | ≥1720 | 2.3 | ||